Choosing the right exterior material in 2026 is a long-term decision. Builders and homeowners now evaluate materials not just on cost, but on durability, maintenance, weather performance, and visual appeal.

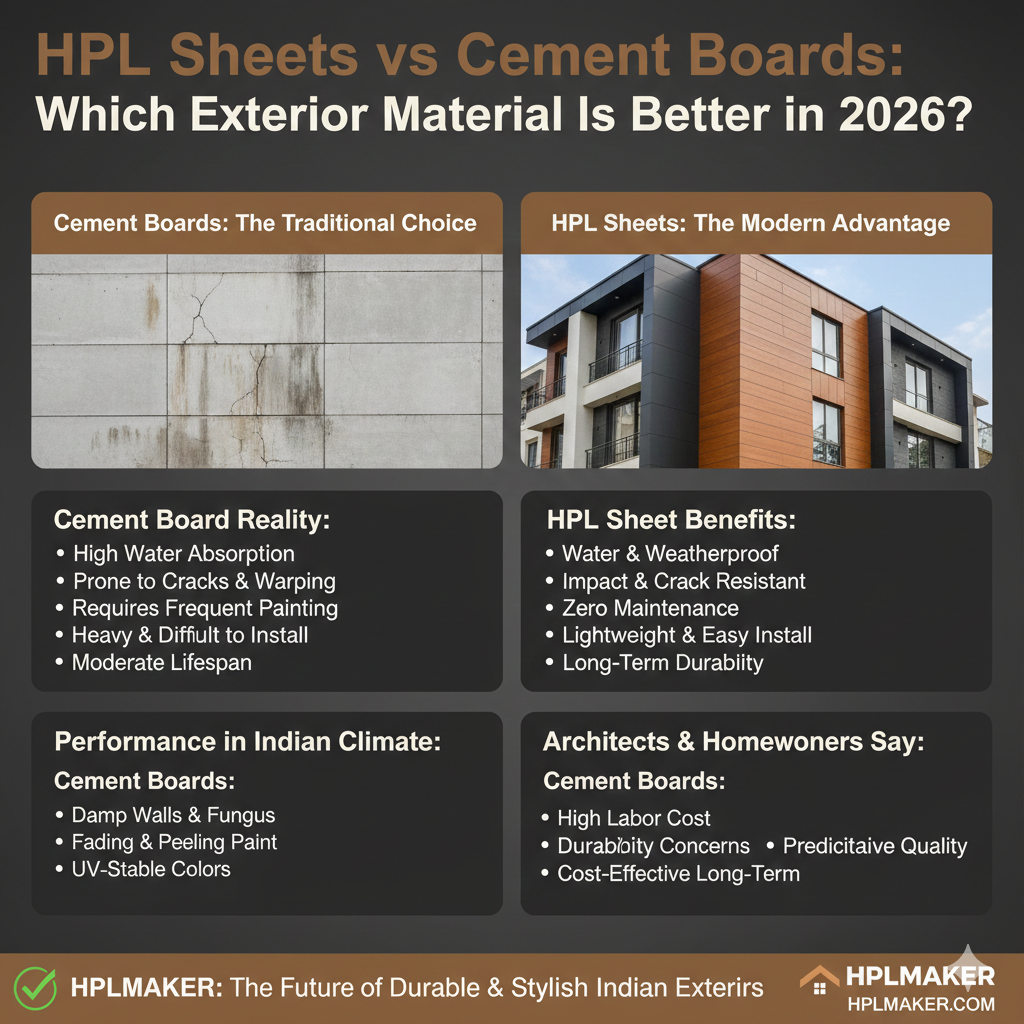

Two commonly used exterior materials are HPL sheets and cement boards. While both are functional, their real-world performance differs significantly over time.

Understanding the Two Materials

What Are HPL Sheets?

HPL (High Pressure Laminate) sheets are manufactured by compressing multiple layers of resin-infused paper under high pressure. They are engineered specifically for long-term exterior use.

What Are Cement Boards?

Cement boards are composed of cement, sand, and reinforcing fibers. They are commonly used as a base layer or for basic exterior finishes.

Durability and Structural Performance

- HPL sheets offer high impact resistance and maintain surface integrity over time.

- Cement boards are strong but can develop cracks due to structural movement or temperature changes.

For areas exposed to environmental stress, flexibility and resilience matter.

Weather Resistance and Moisture Handling

Exterior materials must handle rain, humidity, and temperature variations.

HPL sheets:

- Low water absorption

- Stable in wet and humid climates

- Resistant to surface damage

Cement boards:

- Can absorb moisture if not sealed properly

- Risk of damp patches and surface deterioration

In high-moisture environments, HPL sheets perform more consistently.

Maintenance Requirements Over Time

Maintenance significantly affects long-term costs.

HPL sheets:

- Require minimal cleaning

- Do not need repainting

Cement boards:

- Often require surface coating or paint

- May need repairs over time

Lower maintenance makes HPL sheets more cost-effective in the long run.

Design and Aesthetic Flexibility

Modern architecture demands more than flat surfaces.

HPL sheets provide:

- Wood, stone, and textured finishes

- Clean, modern lines

- Consistent surface quality

Cement boards:

- Offer a plain, industrial look

- Depend heavily on paint or texture coating for aesthetics

For premium designs, HPL sheets offer greater flexibility.

Installation and Project Timelines

Construction speed matters in 2026.

- HPL sheets allow faster installation with dry cladding systems

- Cement boards require additional surface finishing

This difference can significantly affect project timelines.

Long-Term Cost Comparison

While cement boards may appear economical initially:

- Maintenance and repainting increase long-term costs

HPL sheets:

- Have higher upfront value

- Lower lifecycle cost due to durability and minimal maintenance

This makes HPL a smarter investment over time.

Sustainability and Environmental Impact

Sustainable materials are preferred in modern construction.

HPL sheets:

- Long lifespan reduces material replacement

- Lower chemical usage over time

Cement boards:

- Energy-intensive production process

- Frequent surface treatments increase environmental load

Durable materials contribute better to sustainability goals.

Why Builders Are Shifting Towards HPL Sheets

Builders prefer materials that:

- Reduce post-handover issues

- Maintain appearance over years

- Support modern architectural designs

HPL sheets meet these requirements more effectively.

Importance of Choosing the Right Manufacturer

Performance depends on product quality.

Manufacturers like HPLMaker focus on:

- Exterior-grade HPL standards

- Consistent manufacturing quality

- Products aligned with modern construction needs

This ensures reliable exterior performance.

Final Verdict: HPL Sheets or Cement Boards?

In 2026:

- Cement boards are suitable as structural or base materials

- HPL sheets are better suited for finished exterior facades

For durability, aesthetics, and long-term value, HPL sheets are the superior exterior solution.